Mazgaon, Mumbai, Maharashtra

- GST NO. : 27ABCFP8811D1ZC

1.00 / piece

| Business Type | Manufacturer, Supplier, Retailer |

| Application | Electric Equipment |

| Feature | Corrosion Resistant, Fine Finish, Highly Durable |

| Type | Condensing Coils |

| Click to view more | |

Product Details

Country of Origin

India

Product Code

PMR-Condenser Coil

Port

mumbai

These vital components play a crucial role in refrigeration and air conditioning systems. Here’s a concise breakdown of what you need to know:

- Types of Condensing Units:

- Air-Cooled Condensing Units: These units dissipate heat by using ambient air. They’re commonly seen on rooftops or alongside buildings. The cooling process involves a fan blowing air over the condenser coils, releasing heat into the atmosphere.

- Water-Cooled Condensing Units: Instead of relying on air, these units use water as the cooling medium. They’re often found in industrial settings where air-cooling might be less efficient due to high ambient temperatures.

- Hermetic and Semi-Hermetic Styles:

- Hermetic: In hermetic condensing units, the compressor and motor are sealed within a single housing. This design ensures that the refrigerant remains isolated from the external environment. Hermetic units are commonly used in smaller applications like residential air conditioners and refrigerators.

- Semi-Hermetic: Semi-hermetic units have a serviceable compressor. The housing can be opened for maintenance or repairs. These units are more robust and are often employed in commercial and industrial systems.

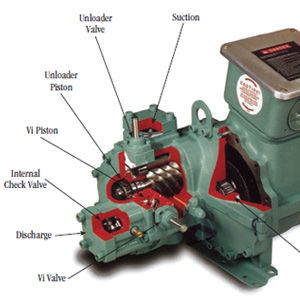

- Compressor Configurations:

- Piston Parallel: This configuration features reciprocating (piston) compressors arranged in parallel. It’s efficient and reliable for various cooling needs.

- Screw: Screw compressors are commonly used in larger systems. They provide continuous compression and are well-suited for industrial-scale applications.

Remember, the efficiency of a condensing unit impacts the overall performance of your cooling system. Whether it’s keeping your ice cream frozen or maintaining a comfortable office temperature, these units quietly work behind the scenes to keep things just right.

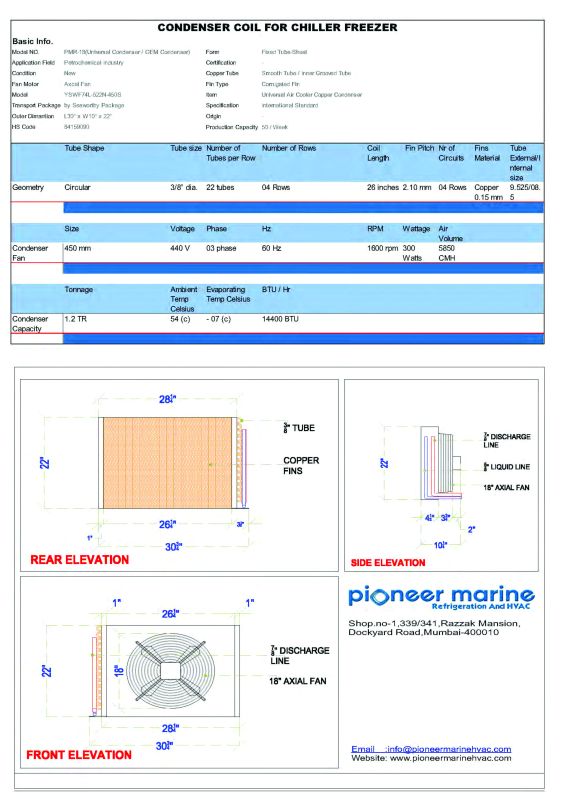

Looking for "CONDENSER COIL FOR CHILLER FREEZER" ?

p

Explore More Products